0 items in quote

.jpg%3Fv%3D3&w=3840&q=75)

1. Granulator (Type SMS 45/60-H5-3): This machine is equipped with a cutting chamber, rotor, and high-quality blades for size reduction. It also includes an extraction system for efficient operation.

2. Air Separation Unit (Type SZS2 450/150): Featuring an air stream separator and adjustable air flow, this unit efficiently separates light materials. It is complemented by a rotatory lock and a suction unit for enhanced performance.

3. Buffer Bunker with Screw: Serving as a material buffer, this component has indicators for monitoring material levels and uses a screw conveyor for controlled feeding.

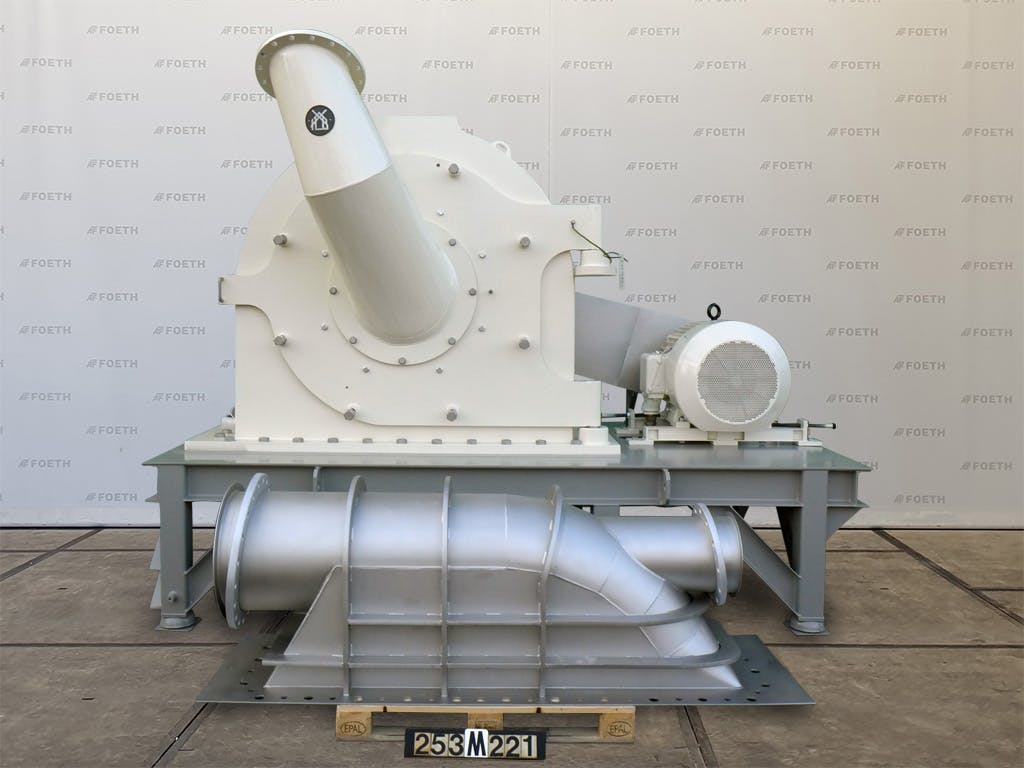

4. Pulverizer (Type PU 800): Designed for processing rubber materials, the pulverizer is equipped with a powerful motor and a metal separator for precise material refinement.

5. Screening Machine (GTS 2000): This machine, driven by a 4 kW motor, is optimized for generating fine powder. It incorporates a rotatory lock for efficient material flow.

The system comprises a range of specialized machinery tailored for plastic processing and material separation. For more detailed information about each machine, please refer to the following expanded descriptions:

The Granulator Type SMS 45/60-H5-3, SN: 21569, built in 2021 with CE certification, boasts a cutting chamber opening of 600x578 mm and rotor measurements of 450 mm in diameter and a cutting width of 580 mm. It features 5 rotor blades and 3 stator blades, all crafted from high-quality D2 chrome-nickel tool steel. Powering this machine is a 75 kW motor operating at 400/690 Volts and 1500 rpm.

Additionally, it includes an extraction system: Type MFR 35/300 with a 7,5 kW motor, operating at 400/690 Volts, and a maximum air flow of 35 m³/min.

The Air separation unit, Type SZS2 450/150, SN: 21571, features an air stream separator channel designed in a zig-zag pattern for easy maintenance. The separation of light materials is achieved through a suction blower, drawing air counter to the material flow within the channel. The air stream can be adjusted using a frequency converter. The channel's cross-section measures 450x150 mm.

Furthermore, it comes equipped with a rotatory lock, Type ZSL 315-400, SN: 21572, CE certified, with a maximum RPM of 38. It also features a suction unit, Type MFT 30/300, with a 4 kW motor, operating at 400/690 Volts, and a maximum air flow of 30 m³/min.

The Buffer Bunker with a screw has an approximate volume of 1 m³ and serves to buffer pre-ground material. It includes indicators for both full and low levels and employs overload-controlled feeding to supply material to the pulverizer via a transport screw.

The screw conveyor, Type RS170, SN: 21575, is 4650 mm long, driven by a 1.5 kW motor at 45 rpm, with a capacity of 0.3 t/h (EPDM SG 0.4 t/m³, inclined at approximately 50°). It also features the same rotatory lock, Type ZSL 315-400, SN: 21572, CE certified, with a maximum RPM of 38.

The Pulverizer Type PU 800, equipped with a screen, bears the SN: 21577 and was produced in 2020. It features a 110 kW motor operating at 400/690 Volts, designed for processing rubber materials. Additionally, it includes a metal separator, Quicktron 03 R, SN: 21578.

This machine also incorporates a suction unit, MFT 100/1000, SN: 21579, CE certified, with a 30 kW motor operating at 400/690 Volts, and a maximum air flow of 100 m³/min.

The Screening machine, GTS 2000, SN: 21581, is equipped with a 4 kW motor operating at 400/690 Volts, designed for generating powder in the range of 0,4 to 1 mm. The screen diameter measures 1600 mm.

Similar to the previous equipment, it is also equipped with a rotatory lock, Type ZSL 315-400, SN: 21572, CE certified, with a maximum RPM of 38.

.jpg%3Fv%3D3&w=3840&q=75)

.jpg%3Fv%3D3&w=3840&q=75)